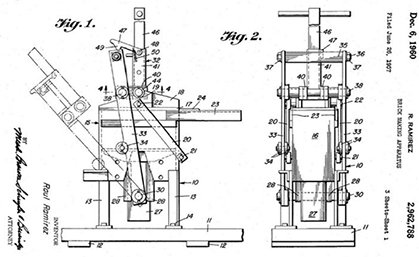

Cinva Ram

The Cinva Ram was designed by Raul Ramirez in 1956, in response for the need for a strong, solid material for the use of housing in South America (due to recent earthquakes that had left a wake of destruction). There were two conditions Ramirez was trying to address, 1. a product/methodology of construction that could be easily constructed by anyone (hence offering cost effective construction for the economically depressed and) 2. Could perform well in seismic zones with fair to superior resilience. The seismic resilience is partially achieved and varies with the unit masonry shapes that can integrate with rebar and/or interlock when stacked. There are different masonry shapes that vary between proprietors.

The masonry created is typically known as an ‘earth block’, suggesting the use of rammed earth as the medium. Rammed earth is a recipe that varies over time and between builders. See our discussion of rammed earth. This process has seemed to have evolved to the modern day creation of dry press concrete pavers. And while likewise each recipe varies between builders, it is essentially a typical concrete mix-with only enough water for it to hold it’s shape and zero slump. Just enough water to form a ‘mud-ball’ when squeezed between your hands. Wikipedia has some accessory information that might be useful.

The original concept was to provide cost effective shelter to the world’s poor. Interestingly, this seems like a product that as it is re-imagined as mostly green (environmental). This invention allowed for the use of free materials (soil) combined with stabilizer. There are two sites that construct and sell Cinva Rams:

Greentek (located in San Diego area)

Gracomaq (located in Columbia) . The Gracomaq design has a hopper in the design speeds up the Production. They are located in Columbia, so for some this might be a barrier.

The point of this blog is to be a share point of information so that this invention is not lost to time. Dejong Architecture is currently having a Cinva Ram Press constructed by Borne Industries (Lethbridge). We believe a Canadian fabricator of this product would makes sense.

Want to build one yourself? Downloads (from open source ecology):